Why Rigorous Inspection & Controlled Access are Best Practices for Scrap Metal Recycling

Scrap metal diversion and recycling is a common component of nearly all transfer stations and recycling centers, transforming discarded materials into valuable resources and serving as an important source of revenue for many municipalities. However, scrap metal recycling also carries inherent risks, particularly the potential for fires, explosions, and injuries caused by hidden dangers such as batteries, fuels, and pressurized tanks. To mitigate these dangers, robust safety protocols, specifically two-stage inspection and controlled access for customers, are not merely best practices—they are indispensable for the safe and efficient operation of any facility.

The article, "Hidden Dangers in Your Scrap Pile," includes a scrap metal hit list of hazardous items (batteries, fuels, ammunition, etc.) underscores the very real threat posed by improperly handled materials. These items, if allowed into the main scrap stream, can lead to devastating consequences: property damage, environmental contamination, and severe harm to staff and the public. This is where a proactive, multi-layered approach to material intake plays a central role.

Check out our sign library for Scrap Metal Signage or read to the bottom!

The Power of Two-Stage Inspection

The examples from several New Hampshire towns illustrate effective strategies for implementing two-stage inspection. This process ensures that dangerous materials are identified and separated before they become a critical risk.

KISS Method: Loudon's simple 2-stage setup (pictured below) allows for customers to leave material next to the container, so that attendants can separate potentially dangerous items, like the lawnmower in the back.

Ground-Level Scrutiny: Grantham's approach is a prime example of rigorous initial inspection. Residents are required to check in with staff prior to dumping any material, regardless of what it is. They then deposit scrap on the ground for a manual inspection. In this way, the facility creates a crucial first barrier. This hands-on examination allows staff to carefully check for hidden batteries, residual fuels, or any other prohibited items that could cause an incident. This direct interaction and immediate inspection are vital for catching hazards that might otherwise go unnoticed.

Gated Access and Periodic Checks: Henniker's one-way traffic flow and gated access demonstrate the importance of controlled entry. Residents first must have their load fully vetted by an attendant at the recycling building. While residents then unload directly into the scrap container themselves, the attendants perform "several periodic inspections of the container" to catch anything missed in the initial check. This multi-layered approach, combining an initial gate-check with ongoing container inspections, provides an important safeguard against contaminants.

Attendant and Operator Double Check: Sunapee takes a slightly different, but equally effective, approach by having both an attendant and a loader operator check the material that residents have unloaded onto the ground. The attendant performs an initial check before the material even reaches the metal area, and then the loader operator provides a crucial "double check" before the material is placed into the container. This redundancy significantly reduces the likelihood of hazardous materials making it into the main scrap pile.

The common thread in these successful models is the understanding that a single inspection point is rarely enough. Human error, oversight, or even deliberate concealment of dangerous items can occur. Two-stage, or even multi-stage, inspection creates a robust system of checks and balances, significantly enhancing safety.

The Benefit of Staff-Only Access to Scrap Containers

The direct access of customers to scrap metal containers can pose a significant risk that ought to be eliminated whenever possible. In Loudon residents dump on the ground next to the container for staff inspection, highlighting the safest practice.

Similarly, in Hollis, customers first drop off scrap metal into a designated area (pictured below) away from the scrap metal container, so that attendants can sort through the pile before it is moved to the containers to be hauled.

The Hollis scrap metal container is set away from customers and clearly posted with "no trespassing" signage (pictured below).

The customer isn't always right

(why customer access to scrap metal containers is so dangerous)

Lack of Training and Awareness: Customers, however well-intentioned, are typically not trained in identifying dangerous materials like concealed batteries, pressurized tanks, or ammunition. They may unknowingly dispose of items that pose an immediate threat.

Impatience and Expediency: In a busy recycling facility, customers may be inclined to quickly offload their materials without proper attention to safety guidelines or a thorough understanding of what's prohibited.

Concealment of Prohibited Items: Unfortunately, some individuals may attempt to dispose of waste or items that incur a fee by hiding them within their scrap metal, hoping they will go unnoticed if directly deposited.

Risk of Injury: Scrap metal piles are inherently unstable and contain sharp edges, heavy objects, and potential fall hazards. Allowing untrained customers to navigate and unload within these environments dramatically increases the risk of cuts, crushing injuries, or falls.

Operational Interference: Customer presence in and around the scrap container can interfere with the safe operation of heavy machinery like loaders and forklifts, creating blind spots and increasing the potential for accidents involving both personnel and equipment.

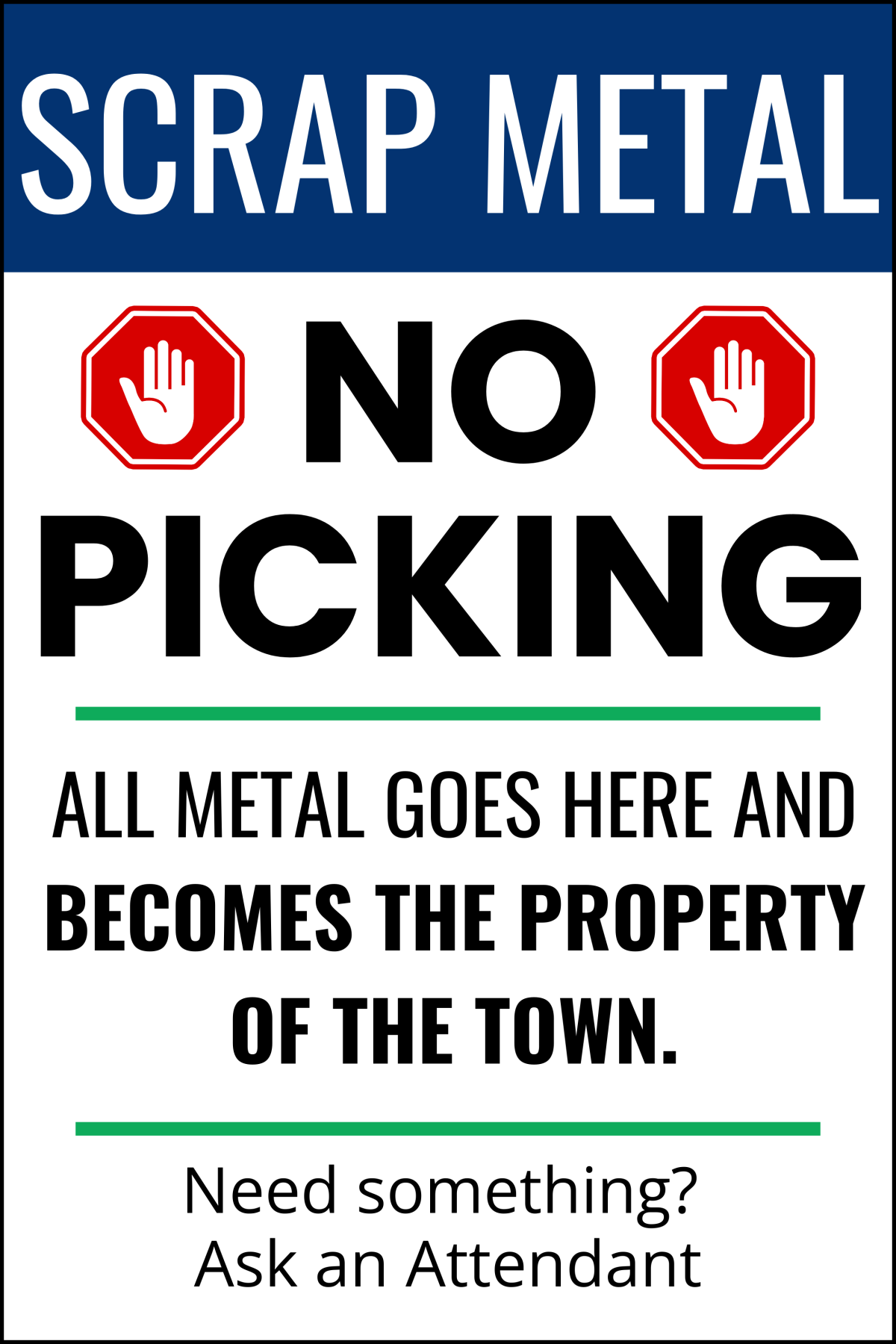

Scrap Metal Signage

NH Recycles has created several signs that can be printed at your local print shop and displayed in an a-frame (this way, you can move the sign wherever you need it!) You can also save the digital format to display the information on a town website or social media. These images are free to print and display.

Scrap Metal - Stop Here Sign (PDF)

Scrap Metal No Picking Sign (PDF)

Conclusion: Prioritizing Safety Through Systemic Control

The safe operation of a transfer station or recycling facility hinges on a commitment to proactive risk management. Implementing a two-stage inspection process is a vital safeguard against the known and hidden dangers lurking in scrap piles. Furthermore, restricting direct customer access to scrap metal containers and allowing only trained staff to handle and sort materials, is a non-negotiable step to protect both employees and the public.